How to Use Anchor Bolts Safely in Concrete Foundations

Anchor bolts play a crucial role in the stability and safety of any structure that connects steel, timber, or machinery to a concrete base. When installed correctly, they provide a secure connection that transfers load, prevents movement, and maintains the structural integrity of the foundation.

In this guide, the BoltBox team explains how to use anchor bolts safely in concrete foundations — covering the types of anchor bolts available, correct installation methods, and the common mistakes to avoid on site.

What Are Anchor Bolts?

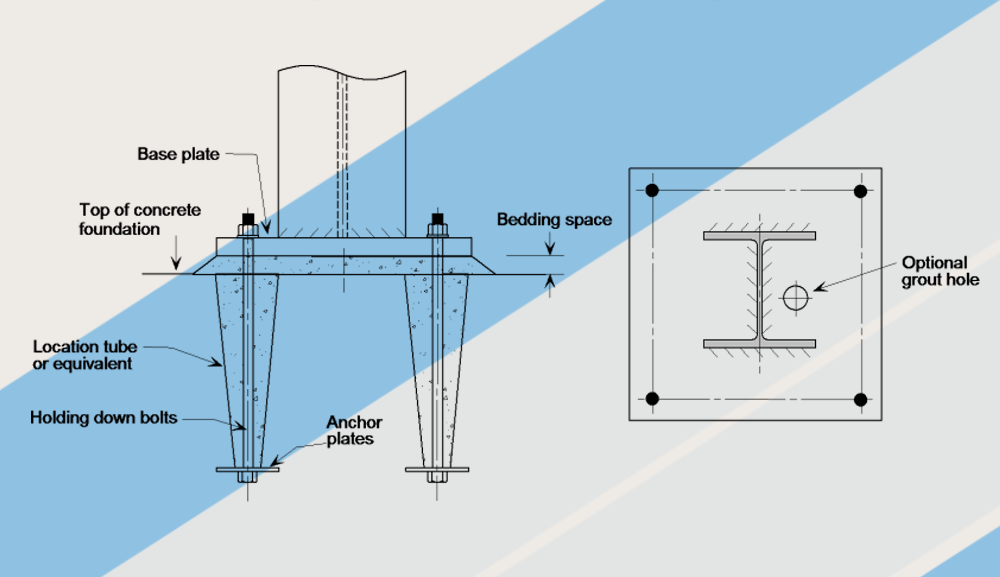

Anchor bolts (sometimes called foundation bolts or holding down bolts) are steel fasteners used to connect structural or mechanical elements to concrete.

They can be:

- Cast-in during the concrete pour, or

- Post-installed into hardened concrete using mechanical expansion or resin systems.

Each type serves a specific purpose depending on load requirements, design codes, and site conditions.

Common Types of Anchor Bolts

| Type | Description | Typical Use |

|---|---|---|

| Cast-in Bolts | Placed before concrete pour using bolt boxes or templates. | Structural steel columns and baseplates. |

| Mechanical Expansion Bolts | Inserted into drilled holes; expand when tightened. | Retrofitting or lighter-duty anchoring. |

| Resin (Chemical) Anchors | Bonded into holes with chemical adhesive. | Heavy loads or close edge distances. |

| Sleeve / Through Bolts | Used for attaching equipment to existing concrete. | Fixing machinery, guard rails, or plant bases. |

✅ Tip: For permanent structural applications (e.g. column bases), cast-in anchor bolts are the safest and most reliable choice.

Choosing the Right Anchor Bolts for Concrete Foundations

Selecting the correct anchor depends on:

- Load requirements: tensile, shear, and combined forces.

- Concrete strength and thickness.

- Exposure conditions: use galvanised or stainless bolts for external or coastal sites.

- Design standards: in the UK and Ireland, foundation bolts should comply with BS 7419 and relevant EN ISO specifications.

BoltBox supplies anchor bolts in M12, M16, M20, and M24 sizes — with nuts, washers, and waxed cardboard cones to simplify installation and protect threads during concrete pouring.

Safe Installation Procedure (Cast-In Anchor Bolts)

Follow these steps to ensure accurate placement and long-term performance:

Step 1 — Prepare the Base

- Confirm bolt locations using approved foundation drawings or templates.

- Ensure the shuttering and reinforcement are correctly positioned.

- Clean the area to remove debris, oil, or water.

Step 2 — Assemble and Position Bolts

- Secure bolts within bolt boxes or sleeves to maintain vertical alignment.

- Use square plate washers at the base for even load distribution.

- Double-check spacing, projection height, and orientation before pouring.

Step 3 — Concrete Pouring

- Pour concrete carefully to avoid disturbing bolt alignment.

- Use vibration to remove air pockets but avoid direct contact with the bolts.

- Keep threads protected using waxed cardboard cones or plastic caps.

Step 4 — Curing and Removal

- Allow concrete to cure as per specification (typically 7–28 days).

- Remove cones carefully to expose clean bolt threads.

- Apply anti-corrosion protection or galvanised coatings if required.

Step 5 — Baseplate Installation

- Lower the baseplate or steel column into position.

- Fit washers and nuts; tighten gradually using a torque wrench to the specified value.

- Check alignment and level before final tightening.

Safety Checks and Best Practices

To ensure long-term reliability and compliance:

- Inspect bolts before installation for damage, rust, or thread wear.

- Use calibrated tools for tightening — overtightening can cause cracking or thread damage.

- Perform a pull-out test (in accordance with BS 8539) if required by design or site engineer.

- Avoid altering embedded bolts after pouring — doing so can compromise anchorage strength.

- Document all installation details (torque values, batch certificates, curing times) for quality assurance.

Common Mistakes to Avoid

| Mistake | Risk | Prevention |

|---|---|---|

| Misaligned bolts | Column or baseplate won’t fit | Use templates or pre-marked jigs |

| Incorrect projection height | Bolt threads too short for nuts | Check dimensions before pouring |

| Using non-galvanised bolts outdoors | Premature corrosion | Use galvanised or stainless finishes |

| Poor concrete compaction | Reduced bond strength | Use vibration and correct mix |

| Over-tightening nuts | Thread stripping or cracking | Use torque wrench and manufacturer data |

Maintenance and Inspection

Anchor bolts should be periodically checked as part of ongoing structural maintenance, especially in industrial or exposed environments. Look for:

- Rust, corrosion, or moisture ingress around the baseplate.

- Loosened nuts from vibration or load movement.

- Cracked or spalled concrete near bolt edges.

If deterioration is found, consult a structural engineer for assessment or replacement advice.

Why Choose BoltBox for Foundation Fixings

At BoltBox, we supply a complete range of holding down bolts, bolt boxes, square plate washers, and waxed cardboard cones — manufactured in the UK to meet BS 7419 and related structural standards.

Our components are designed to simplify installation, maintain accuracy, and deliver long-term reliability on site.

🔗 Explore our full range of Holding Down Bolt Sets and Waxed Cardboard Cones.

Key Takeaways

- Always select anchor bolts based on load, environment, and standards compliance.

- Follow a controlled installation process using templates and protective cones.

- Perform torque checks and inspections to maintain safety and performance.

- Use galvanised, certified components for long-term corrosion protection.

📞 Need Technical Advice?

Our technical team can help specify the correct holding down or anchor bolt systems for your project.

Contact us today for expert guidance or a free, no-obligation quote.