Holding Down Bolts Lancashire

We supply a range of Holding Down Bolts Nuts & Accessories to Lancashire businesses. We also manufacture and supply bespoke bolts and accessories to suit your company requirements.

Holding Down Bolts, Anchor bolt, foundation bolt or holding down bolts

What are holding down bolts used for?

A holding down bolt is a steel bolt usually fixed in a building structure with its threaded portion projecting. Most widely used to secure frameworks, concrete, timbers, machinery bases, etc.

There are many types of holding down bolts, consisting of designs that are mostly proprietary to the manufacturing companies. All consist of a threaded end, to which a nut and washer can be attached for the external load.

At Lancashire BoltBox we manufacture and supply bespoke holding down bolts to your specified bolt requirements, for a one project or a multiple supply for a distribution centre. All manufactured by our company BoltBox in our workshop in house Lancashire

How can you tell if a bolt is holding down?

A rough method of checking holding bolts is the hammer test. Hold the tip of the thumb on one side of the nut face and strike the nut on the opposite side. If the nut is slack, the nut and stud spring against the thumb and then retract. the movement can be felt against the thumb.

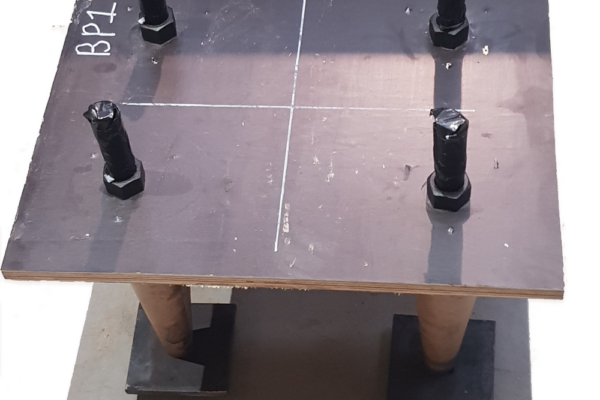

Holding down bolts assemblies are usually set into a ply template that replicates the base plate of your steel work. Wax cardboard cones are used (sometimes referred to as bolt boxes) and glued with loads of Gripfill to the underside of the template to ensure that the cones stay in place whilst shoveling concrete around the assembly. It’s best to assemble the whole lot and leave overnight to set.

Holding down bolts are usually “Set Low” to allow for some vertical adjustment and to allow some room to cover over the nuts with floor screed, When the concrete has set, undo the nuts, pull off the template and the wax cones. The bolts will then be left sticking up in the concrete, put a tube on them and gently wobble them to ensure some lateral movement, this will assist with fitting the columns later.

When the frame is fitted it will drop down the bolts and onto the concrete, now is the time to level the frame up by adding square plate washer packing pieces under the base plates.

It’s best to put the packers dead centre on top of the concrete between the four cone holes, next just nip up the nuts until the bolts have a little tension.

The void under the plate and the cone holes now need to be filled with a non shrink concrete grout.

Knock up a simple frame that fits the column base plate footprint on three side sides but leaves a 2″ gap on the other. Pour the grout into the open side until the grout is level with the base plate. Allow to set, remove the frame and cut of the excess grout and fully tighten the nuts.

Conical Bolt Cones are manufactured from waxed cardboard

When used with a holding down bolt it will provide a conical void for easy bolt location adjustment, with minimum displacement of reinforced concrete

Bolt Cone needs to be 50mm shorter than the actual bolt.

What are Waxed Cardboard Cones used for?

Waxed Cardboard Cones are used to sit holding down bolts into the ground to fix steel or timber frame buildings or structures.

Holding down bolts are steel bolts usually fixed in a building structure with its threaded portion projecting. Holding down bolts are used on the foundation of structures. They are attached with a wooden piece placed on top of the foundation. The bolts help in stabilising a structure.

Square plate washers are used in a variety of applications but are most commonly used with a holding down bolt, straight rod, anchor bolt or sometimes loose. The use of plate washers with holding down bolts can provide a larger surface area to the base of the fixing. This means it would require substantially more force to pull the holding down bolt out of its embedment.

We also supply full steel stanchion bases for overhead signs/windmills/floodlights/ bridge crash barriers etc

CALL THE HOLDING DOWN BOLTS LANCASHIRE TEAM TODAY 07929142325

Please Get In Touch Or Send Your Layout Drawings To “sales@boltbox.co.uk”

We Will Price And Advise On Our Current Lead Times.

BOLTBOX offer services ACROSS THE UK. Wales, Scotland, Ireland, London, Birmingham, Edinburgh, Cardiff, Manchester, Liverpool, Hull, Lancashire, Burnley, Blackburn, Rossendale, Todmorden, Preston and all other locations in the UK. Call for details or email sales@boltbox.co.uk