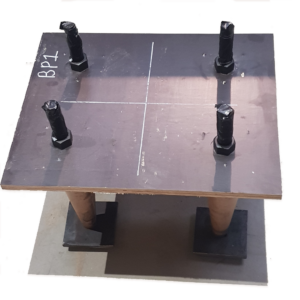

The checking of holding down bolts should be checked by a surveyor at six monthly intervals or more often depending on the construction or vessel. Holding down bolts can get slack more frequently for vessels like ships. You can check holding down bolts on board the ship itself.

In new ships, the bolts should be checked within one month of the commencement of the first voyage, or earlier if possible. Then decrease the intervals allowing a longer length of time between checks if all is found in good order. After a ship/vessel has been through bad weather/storm, the bolts should be checked as soon as possible, as they may have become slack.

A rough method of checking holding bolts is the hammer test. Hold the tip of the thumb on one side of the nut face and strike the nut on the opposite side. If the nut is slack, the nut and stud spring against the thumb and then retract. the movement can be felt against the thumb.

If a holding down bolt is of the fitted type, this test cannot be used, and a hydraulic jack must be used. Due to the presence of bilge water on the tank top at various times, the holding down bolt nuts may rust and seize on the studs.

In this case, the seized condition makes it seam as if the nut is tight. The hammer testing method, however, can be used in finding slack nuts, even when they are seized on a stud.

FOR A QUOTE, TO ORDER OR FOR ADVICE, call 07929142325 or email sales@boltbox.co.uk

BOLTBOX offer services ACROSS THE UK. Wales, Scotland, Ireland, London, Birmingham, Edinburgh, Cardiff, Manchester, Liverpool, Hull, Lancashire, Burnley, Blackburn, Rossendale, Todmorden, Preston and all other locations in the UK. Call for details or email sales@boltbox.co.uk